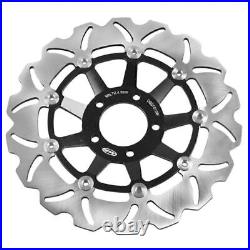

You may also like. 1-1/4″ Hose with 1/8″ NPT Steam Port Adapter Top Radiator LS Swap Steam Coolant. For Audi A3 A4 S4 A5 S5 A6 A7 Red Steering Wheel Shift Paddle Shifter Extension. Passenger Tank Grab Bar Handle Fit Honda CB 600F 599 900F 919 Hornet 600 900 Red. Wheel Eyebrow Arch Trim Side Fender Flare Strip fits Tesla Model 3 2017-20 Blue. Black Front Brake Discs Rotor Fit Suzuki GSF BANDIT 250 & 400 89-96 &1200 96-05. If there is any problem, please contact with us. We would be very glad to help you. 2 x Brake Disc Rotors. (not include weekends and public holidays). Items must be in original box and kept in good condition. We will reply to you quickly and try our best to serve you. Thank you in advance. 4Sets Carburetor Carb Repair Rebuild Kit Fit Kawasaki ZZR600D 1990-92 ZZR ZX 600. LED Integrated Tail Rear Light Brake Turn Signals For Honda Grom MSX125 2014-UP. Ignition Switch Fuel Gas Cap Seat Lock Key Set FOR Honda CRF250L/250LA 2013-20. Front Brake Fluid Reservoir Cover Cap Black For Trident 660 Tiger Sport 660 800.